| |

|

|

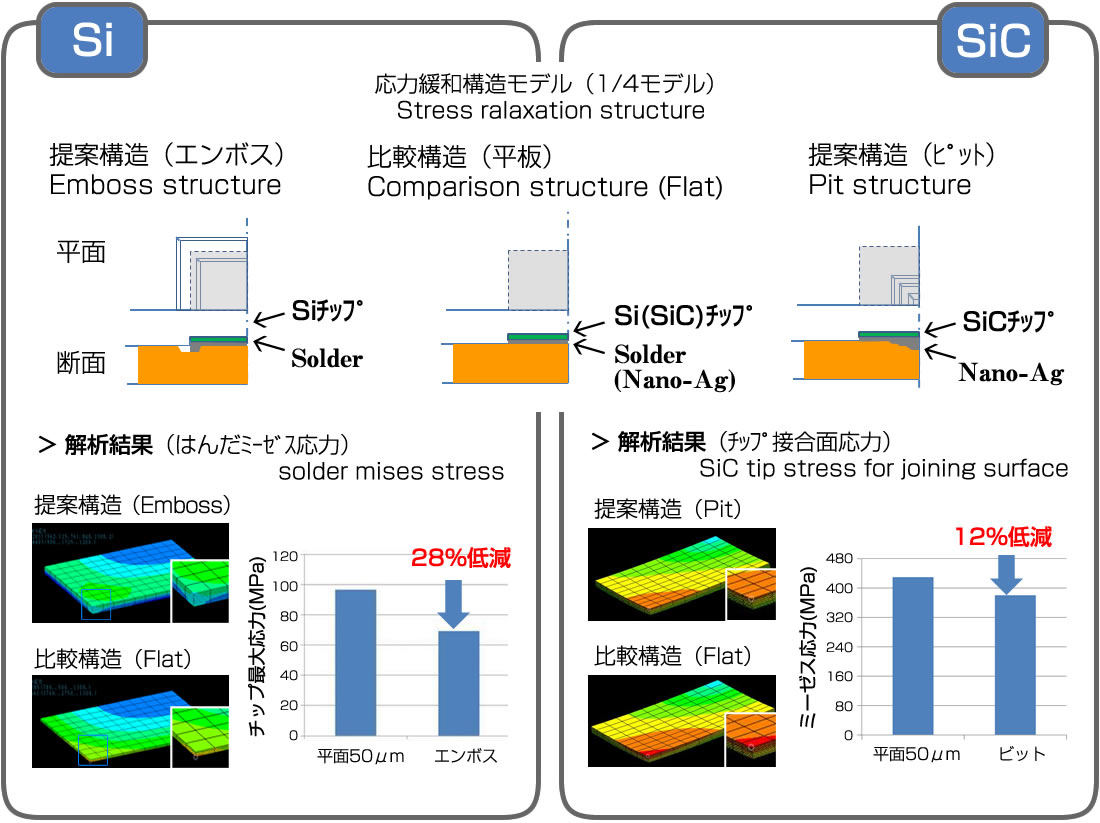

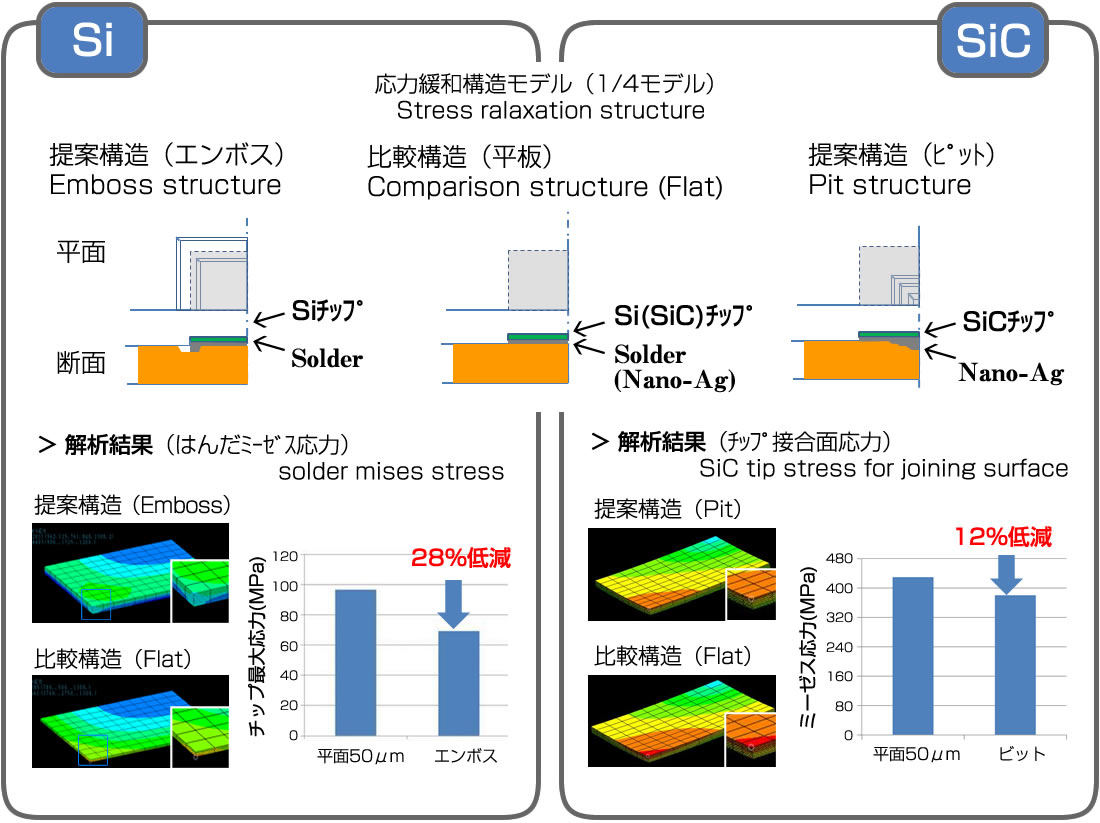

リードフレーム(Cu)と化合物半導体(SiC)の線膨張係数差を

リードフレームの構造で改善する事を提案!

Our Leadframe solve linear expansion coefficient difference problem |

|

|

|

|

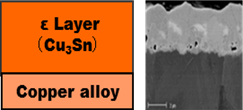

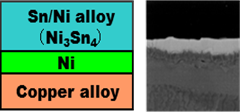

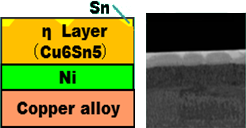

■高温特性 Heat Resistance

| |

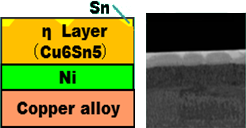

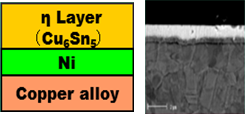

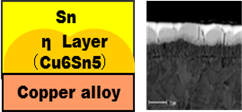

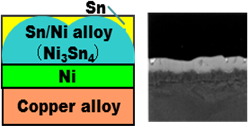

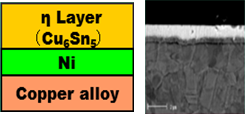

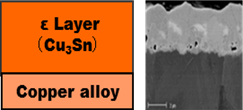

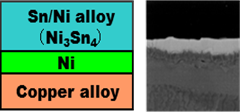

3 Layers Plating |

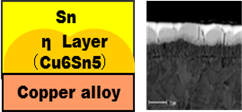

Sn Panting |

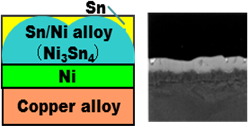

Ni / Sn Plating |

Before heating test

(めっき製品)

Characteristic fore surface |

|

|

|

Hardness : Hv300〜400

No Shaved |

Hardness : Hv < 10

Tin Shaved |

Hardness : Hv100〜160

No Shaved |

| Contact resistance : <3mΩ |

Contactresistance: <1mΩ |

Contactresistance: <1mΩ |

After heating test

(160℃✕3000hr)

Characteristic for surface |

|

|

|

Hardness : Hv300〜400

No Shaved |

Hardness : Hv500〜650

No Shaved |

Hardness : Hv514

No Shaved |

| Contactresistance : <0mΩ |

Contactresistance : <700mΩ |

Contactresistance : <500mΩ |

|

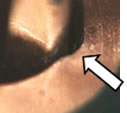

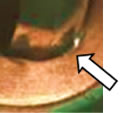

■耐削れ性 Scraping Resistance

|

3 Layers Plating

0μm-Sn Plating |

0.2μm-Snめっき

0.2μm-Sn Plating |

0.4μm-Snめっき

0.4μm-Sn Plating |

0.8μm-Snめっき

0.8μm-Sn Plating |

|

|

|

|

|

| |

Sn削れカス無し

No Shaved Tin Powder |

Sn削れカス発生

(微量)

The powder of shaved tin is least amount |

Sn削れカス発生 Shaved Tin Powder |

|

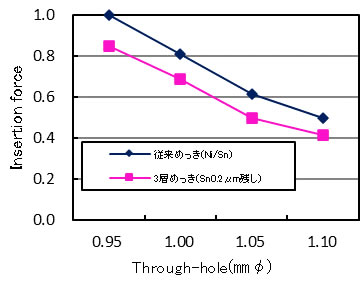

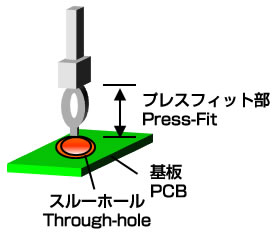

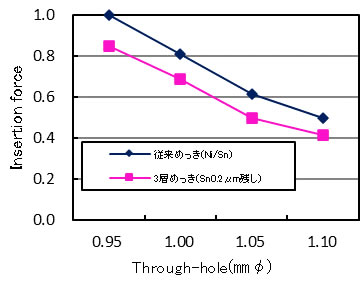

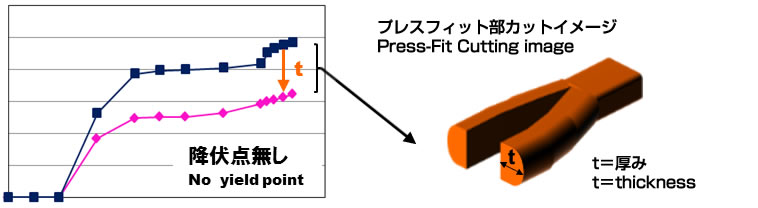

■挿入力 Insertion Force

高い保持力と挿入力の絶対値をコントロール可能

It is possible to control high-holding force and Low-insertion force |

|

|

|

|

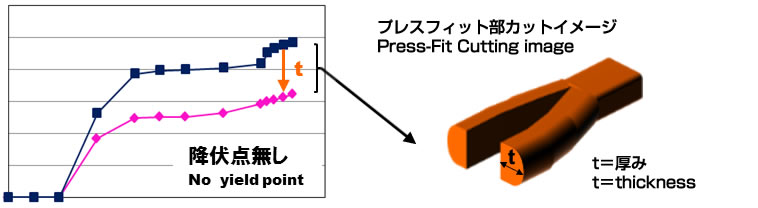

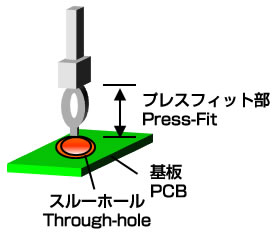

■挿入力 Insertion Force

| 挿入位置(mm) position |

PFの肉厚(t)を変え

挿入力・保持力をコントロール

Insertion force and hokling force controlled

by thickness of press-fit terminal |

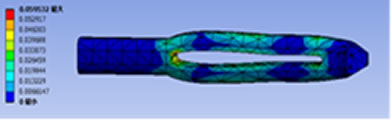

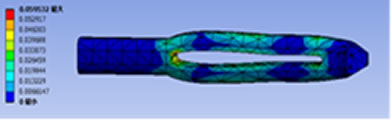

■塑性ひずみ Plastic deformation

当社製品 Our products |

|

|

|

|

|

|